When calculating the earthworks volumes for the site there

will usually be a number of subsurface layers that we will need to take into

account. For example a typical site might consist of 3 layers; a peat layer

overlying an intermediate layer of reusable material under which there is a

rock layer. All of these will probably be intersected by your proposed access

road surface at some point and volumes calculations will involve comparisons

between two or more of these surfaces.

In calculating the volumes we will look at two methods;

Volume Surfaces and Materials from Cross Sections. While using volume surfaces

is a great method for calculating volumes I have found that using materials is

more flexible. You define a material as the volume you wish to calculate. For

example I might create a material called Volume

of Rock Cut and define it using the access road proposed surface and the

top of rock surface. Materials are particularly useful where you have more than

two surfaces bounding your desired volume. It also allows you to generate a

cumulative volumes report for each material on a per cross section basis.

Volumes to be Calculated:

1. Volume of Peat to be Stripped from

Site

This is straight forward. Create a volume

surface using the existing ground surface

as the base and bottom of peat

surface as the comparison. Extract the border from your final corridor top surface

to give you a polyline representing the extents of the works. Add this polyline

to the volume surface as a boundary (This can be added from the Toolspace).

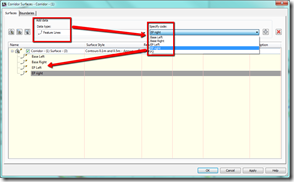

2. Volume Of Rock Cut

This is the volume bounded by the top of rock

and the access road proposed surfaces. Create a material (Sections

menu<Compute Materials) using these two surfaces. Set the Quantity Type and

the Conditions as below:

The conditions in this case are

telling Civil 3D that we want everything above the formation surface and below

the rock surface.

3. Volume of Rock Fill

This is the volume bounded by the bottom of

peat and access road proposed surfaces. Create a material using these

materials. Conditions are everything Below the proposed surface and Above the

peat surface. Quantity Type is Fill. See completed material below.

Volume Cut/Fill Rock Materials on

Cross Sections:

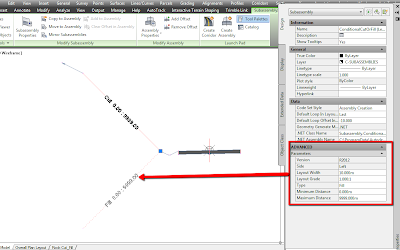

4. Volume Reusable Material Cut

Between the bottom of peat and top of rock

layers on this project there was a layer of material that was deemed competent

enough to be reused as fill elsewhere. The volume required in this case is

bounded by three surfaces; Proposed surface, top of rock and bottom of peat.

Create another material as before adding in

the three surfaces. The Conditions are everything below bottom of peat and

above the other two surfaces, Quantity Type is Cut. See below:

Volume Reusable Material on Cross

Sections:

Once you have your materials

calculated you can generate a volume report – Sections menu<Generate Volume

Report and select the report template you wish to use. This provides an easy to

read cumulative volume report for each of the cross sections.